Our Maintenance Technician Skills courses are designed to give those who are just entering the field, or those who need to expand or refresh their knowledge, the core skills necessary to be successful and work safely in the Industrial Maintenance field.

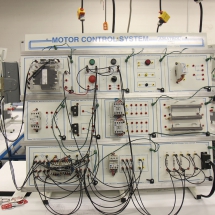

- Applied Industrial Electricity – This 28-hour course provides participants with the skills necessary to safely work with and troubleshoot electrical systems and motor controls.

- PLC Systems Level 1 ControLogix/CompactLogix – This 36-hour course provides participants with practical skills to service and troubleshoot systems using Allen-Bradley ControLogix automation controllers and CompactLogix controllers.

- PLC Systems Level 1 MicroLogix/SLC500 – This 36-hour course provides participants with practical skills to service and troubleshoot systems using Allen-Bradley MicroLogix and SLC500 Programmable Logic Controllers.

- Electronic Drives – This 20-hour course provides participants with the skills required to safely install, program, and troubleshoot modern AC variable frequency drives, servo drives, and stepper drives.

- Troubleshooting Techniques – This 20-hour course provides participants with proven techniques and practices to apply their knowledge of industrial electrical controls to troubleshoot and repair complex systems.

- Mechanical Systems – This 24-hour course provides participants with skills to safely and effectively work on common industrial mechanical systems. Emphasis in the training is directed at performing installation and repairs with techniques to extend service life of machine components.

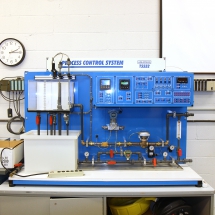

- Fluid Power for Industry – This 24-hour course provide participants with skills required to safely install and maintain hydraulic and pneumatic systems.

- AutoCad Basics – This 8 hour course provides participants with skills required to create or edit 2D AutoCad drawings and blueprints.

Modern manufacturing positions require a much broader range of skills than ever before. In these fully customizable courses, we can help develop your team to gain a broader skillset while meeting your company’s needs.

- Basic CNC Machining – This course offers an introduction to Computer Numerical Controlled machine tool operation and programming.

- Geometric Dimensioning & Tolerancing – This course offers a study of basic geometric tolerancing and dimensioning of machined parts and drawings.

- Blueprint Reading For Industry – This course offers training for manufacturing employees who apply blueprint reading skills in the workplace for accurate product quality inspections and precise adjustment and setup of machinery.

- Applied Shop Computations – This course offers a focus on basic arithmetic and calculations necessary for solving shop oriented problems involving geometric figures, formulas, and algebra.

This certificate program provides basic production skills and more in an 8 week full-time program designed to prepare participants for careers in modern manufacturing. Tuition assistance is available for those who qualify.

- Industrial Safety –This course is designed to provide the student basic information and procedures concerning industrial safely awareness and accident. Successful completers of this training will receive an OSHA-10 Hour Certification from the Department of Labor.

- Manufacturing Skills I – This course is designed to provide the student with a basic understanding of units of measurement and measurement techniques used in the manufacturing industry, fundamentals of creating technical drawings, and various manufacturing skills.

- Manufacturing Skills II – This course is designed to provide the student continued study in hydraulics, pneumatics, electrical systems, mechanical drive systems, automated material handling (robotics), quality control systems, machining, and computer aided drafting.

- Manufacturing Skills III – This course is designed to provide the student with a concentration on electrical theory, motors, and controls with additional time spent on Quality Assurance, Fluid Power, and Mechanical Drive Systems.

- Manufacturing Skills IV – This course is designed to provide the student with a concentration on Programmable Logic Controllers with additional time spent on Fluid Power, Mechanical Drive Systems, and Electrical Motor Controls.

- Applied Shop Computations – This course is designed to provide the student a focus on basic arithmetic and calculations necessary for solving shop oriented problems involving geometric figures, formulas, and algebra.

- Special Topics In Technology – This course is designed to provide the student with information regarding the fundamentals, principals, and practices of Industrial Technology. The course covers basic through advanced procedures associated with current technology.

- Education To Careers – This course is designed to provide the student with orientation for transitioning from education to careers including interview techniques, resume writing, job search strategies, personal growth, and finance.

Our Safety and Quality programs provide the training and certifications required by many industries and manufacturers to operate in compliance with government regulations while meeting their customer’s requirements.

- Lead Safety Certification – This course prepares competent employees to achieve U.S. Environmental Protection Agency Lead Certification for performing renovations, repairs, and painting in residential and childcare structures built before 1978.

- OSHA 10 Hour Certification – This online general industry course is designed to provide the student basic information and procedures concerning industrial safely awareness and accident. Successful completers of this training will receive an OSHA-10 Hour Certification from the Department of Labor.

- OSHA 30 Hour Certification – This online general industry safety course is designed for credentialing leaders, supervisors, and managers to oversee safe plant floor practices. Successful completers of this training will receive an OSHA 30 Hour General Industry completion card from the Department of Labor.

- NFPA 70E Arc Flash Awareness – This one day seminar is designed to teach awareness and understanding of NFPA 70-E and why it is important. This course is offered as an initial certification or a refresher.

- Quality Control – This course provides the student with the basic concepts and terminology for the field of quality control and quality management.

- 5S/6S – This course provides the student with skills to optimize productivity in their work environment through implementation of the 5S/6S pillars and the reduction of waste.

- Six Sigma Green Belt Certification – Participants involved will learn how to approach this data driven measure of quality that strives for near perfection. This course will offer an introduction to the Six Sigma philosophy and the DMAIC model. Participants will then be asked to complete a project following the DMAIC format that can achieve real savings in the workplace. Based on the ASQ/Body of Knowledge, this course will also stress the importance of the following:

- Working as a team to facilitate the Six Sigma improvement process

- Reduce variations in process output

- Eliminate defects through an advanced process

- Problem Solving – Problem Solving & Root Cause Analysis teaches a structured problem solving process using the 8-D model. This model utilizes a team approach to problem solving and provides a structured step-by-step format that is easily implemented in any type of business.